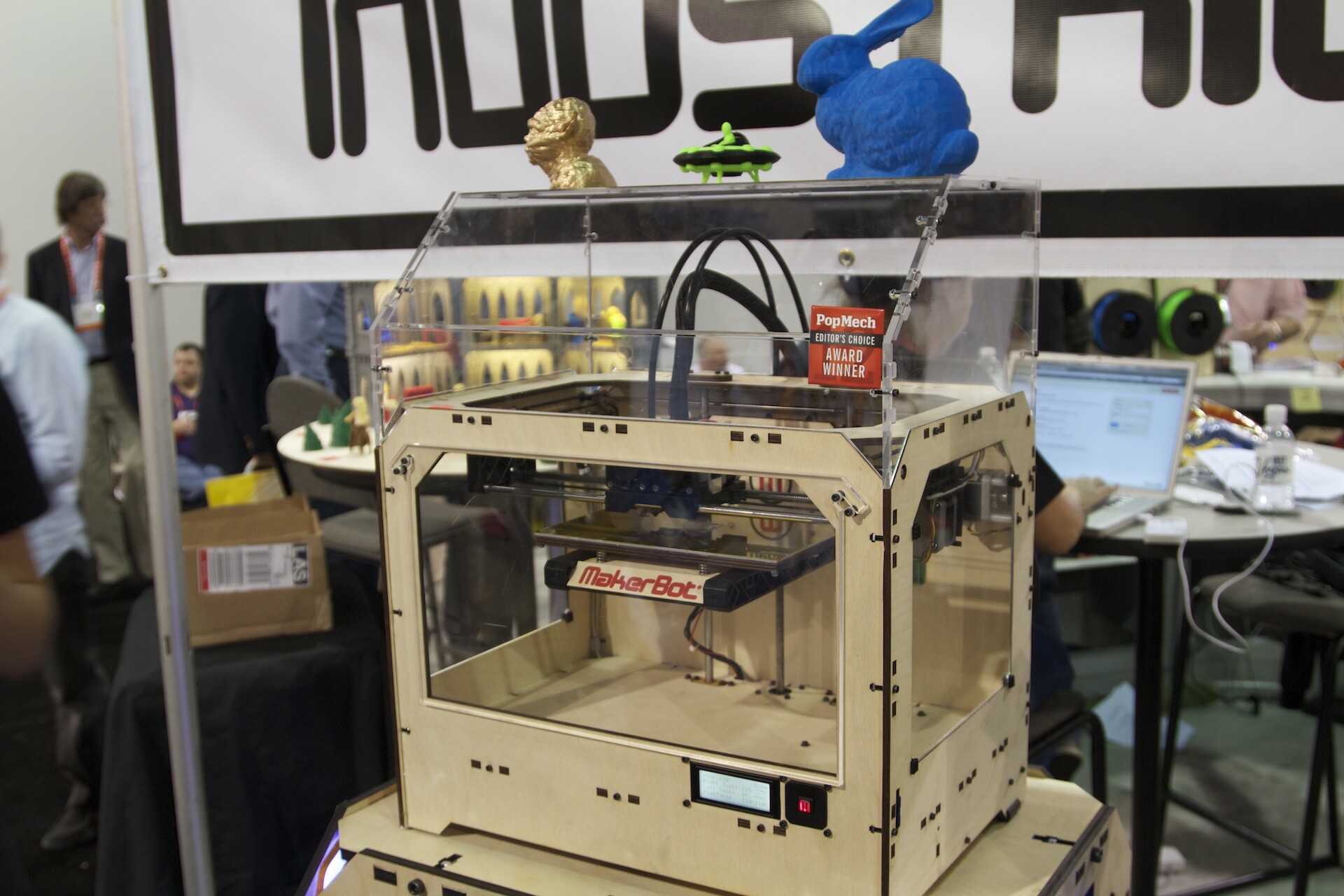

The folks at MakerBot Industries have not exactly been resting on their laurels since causing a stir at CES last year with the Thing-o-Matic 3D printer. Even though the original small object creation device would still see the jaws of most people dropping in wonder, the company has now unveiled a new model at CES 2012 called the Replicator that is not only capable of fabricating much bigger objects than its predecessor, but can also do so in two colors at the same time.

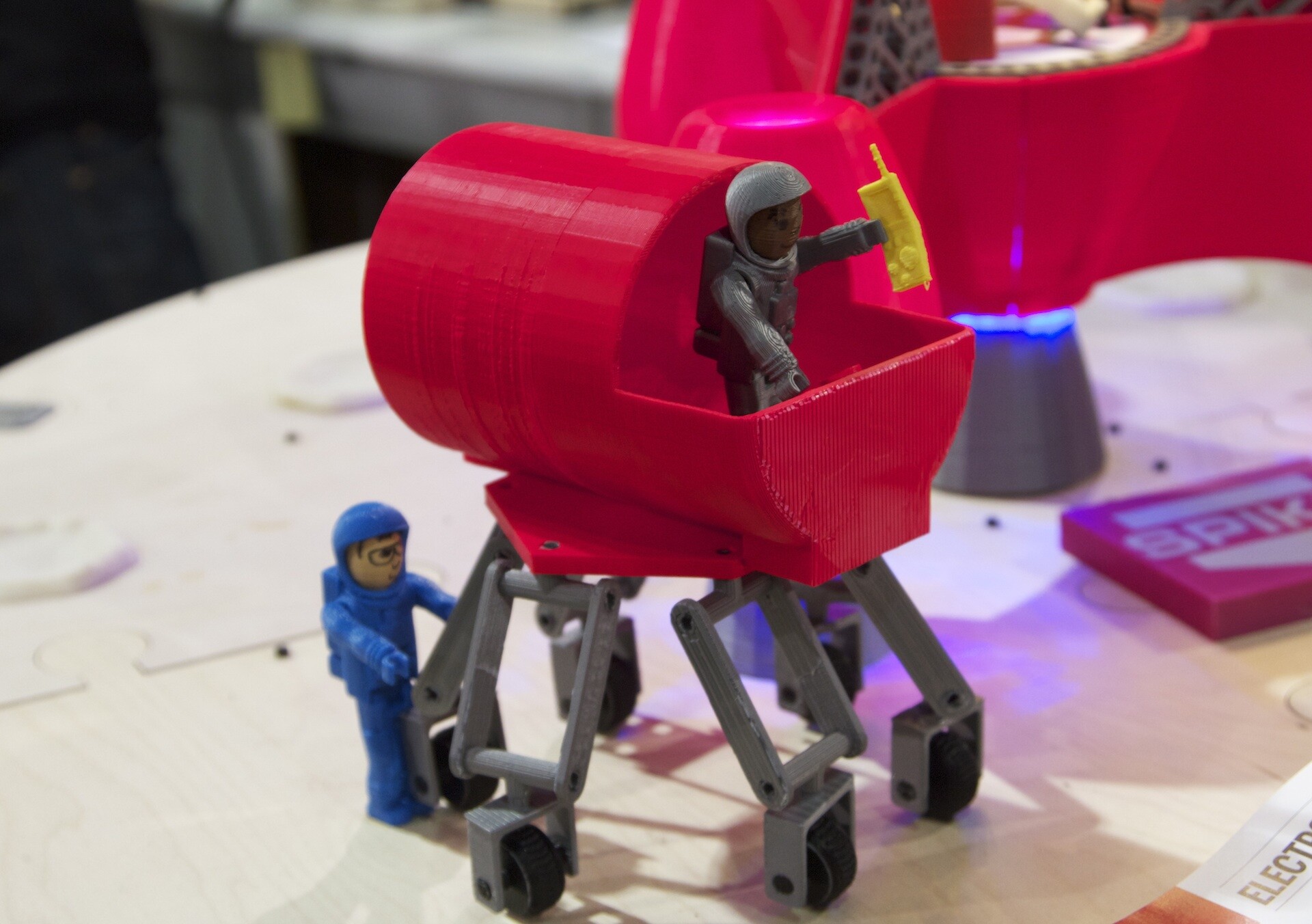

Rather than having some fabrication company on the other side of the world mass-produce millions of plastic shower curtain hooks, door knobs, or even chess pieces and then ship them to your local store for you to buy, desktop-friendly 3D printers like MakerBot's Thing-o-Matic allow users to create every day objects in the home, only when are were needed. Revolutionary!

Now, I'm no stranger to side-stepping the world of big commerce to get what I need. There was a time in my not-so-distant past when I used to spend my spare time pouring resin into floppy molds, wait a few hours for all the chess pieces to set and then smooth, polish or paint the finished objects until they were smart enough to give away as presents. By MakerBot standards, though, my efforts were positively prehistoric.

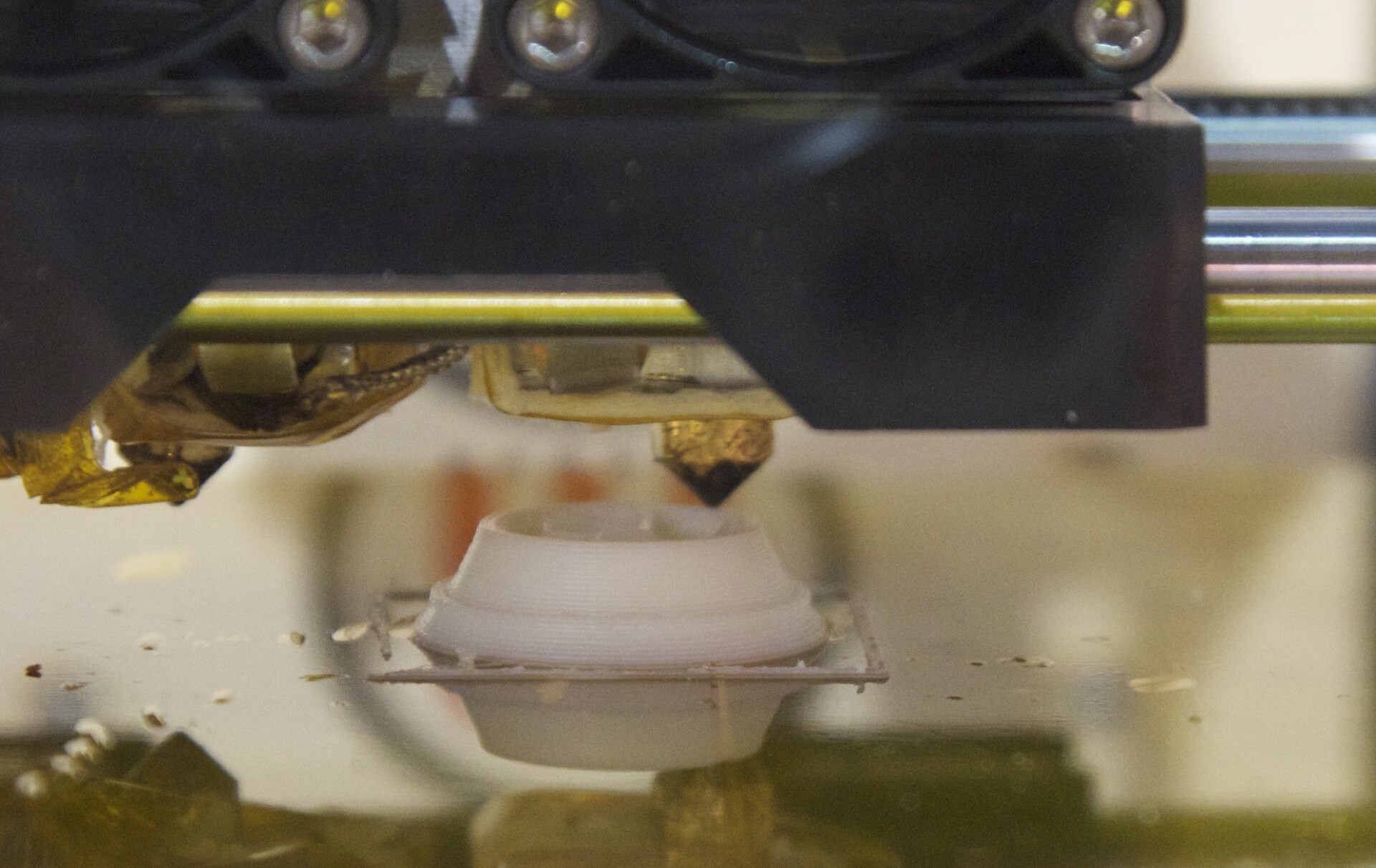

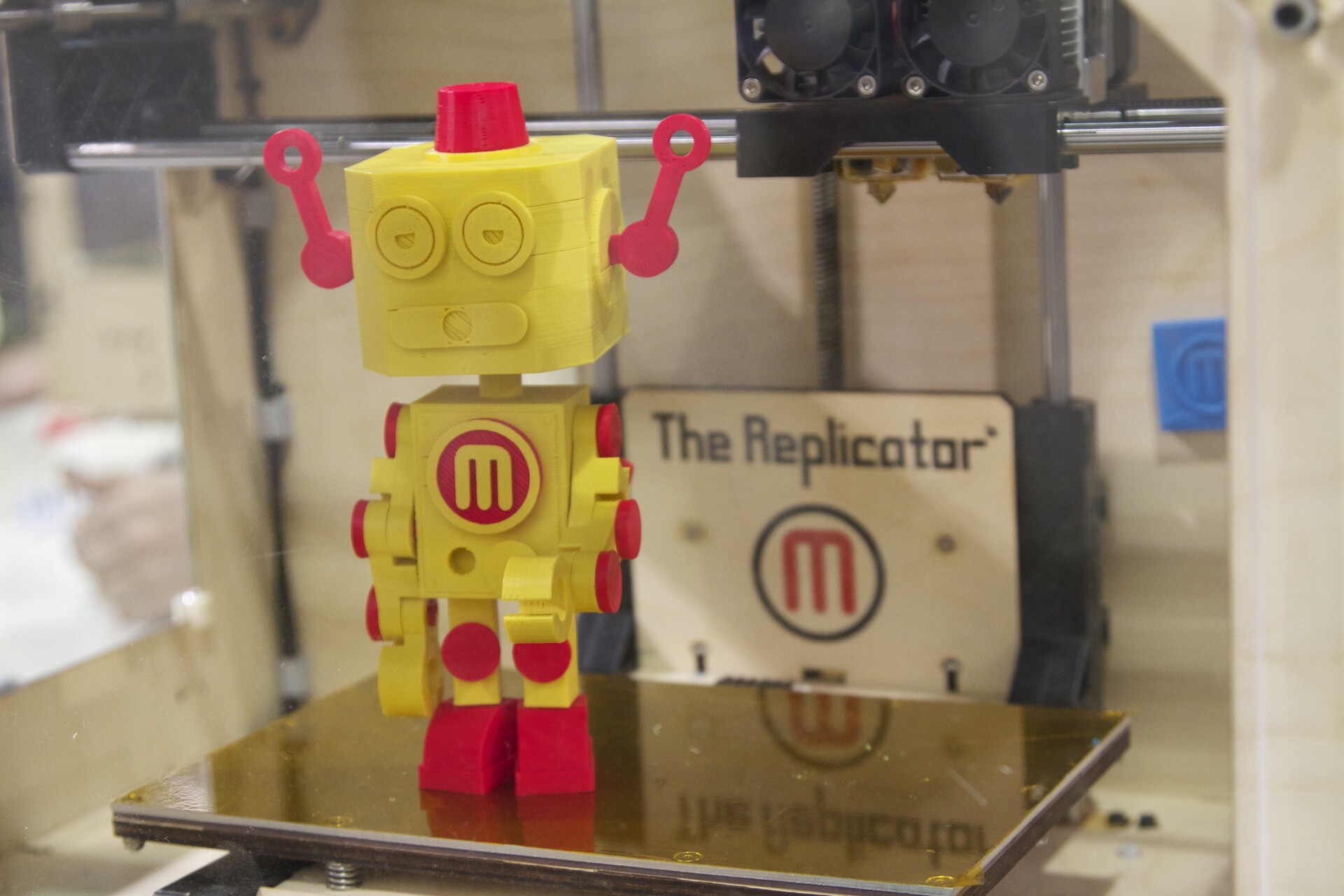

With the next generation of MakerBot 3D printer, users will be offered the chance to increase the print volume from objects about the size of a cupcake in the Thing-o-Matic up to roughly the same size as a loaf of bread in the Replicator - or something in the region of 9 x 6 x 6 inches (228.6 x 152.4 x 152.4 mm). The new device features an upgraded MK8 version of the MakerBot Stepstruder (that's the bit that actually transforms raw materials like ABS plastic or bio-degradable PLA into 3D objects) that prints at a speed of 40 mm (1.57-inches) per second. The company is also now making it possible to simultaneously print objects in two colors via dual extruder heads.

The new 12.6 x 18.4 x 15-inch (320 x 467 x 381 mm) Replicator weighs 30 pounds (13.6 kg) and now includes its own built-in, four line LCD panel and game-controller-like user interface to allow for computer-free operation. Object model designs can be loaded directly into the control pad via an SD card slot, or via USB connection to a Linux, Windows, or OS X computer.

Unlike its kit-based predecessor, the new beast is pre-assembled by hand by MakerBot's engineers in Brooklyn, New York and tested before being shipped out, making it ready for action as soon as it arrives.

The new Replicator is currently showing as available for pre-order. A single extruder unit and a 1 kg (2.2 pounds) spool of natural ABS plastic is priced at US$1,749, with a further US$250 securing the purchase of the model featuring MakerBot's dual extruder - or Dualstrusion - technology and two spools of plastic - one natural, one black.

Comments

Post a Comment